Helix Cables

GEMO helix cables for roof opening and shading systems

Key initial selection criteria:

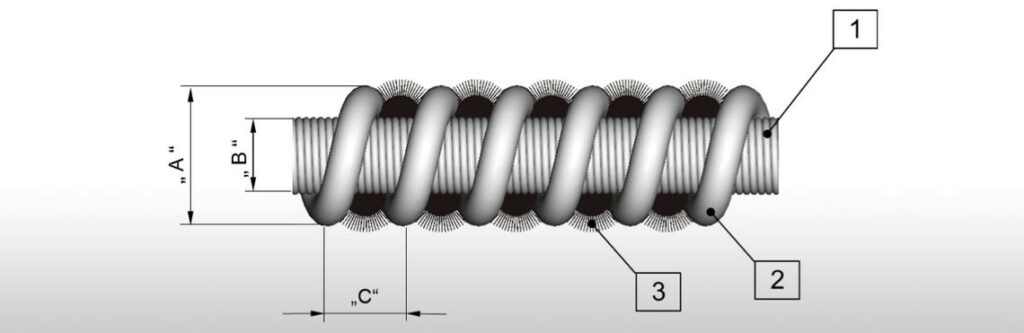

The standard helix cable comprises:

- core

- helical/helix wire Ø 1.2 +/- 0.03 mm

- flock yarn

Dimensions and tolerances for the standard helix cable for roofs and shading systems:

A = outside diameter 4.7 +/- 0.05 mm

B = core diameter 2.6 +0.2 mm

C = pitch 2.54 +/-0.04 or 2.55 +/- 0.04 mm

For a significant improvement of corrosion properties and further reduction of potential noise emissions, we recommend that the helix cables be oiled by GEMO.

The different technical properties of the helix cables are determined by the type of core used. The core can be a flexible shaft or a wire. The helical/helix wire is identical in the standard versions.

Flexible shaft core Multiple thin wires in three layers

Flexible shaft core Small number of larger diameter wires in two layers

Wire core High performance cable

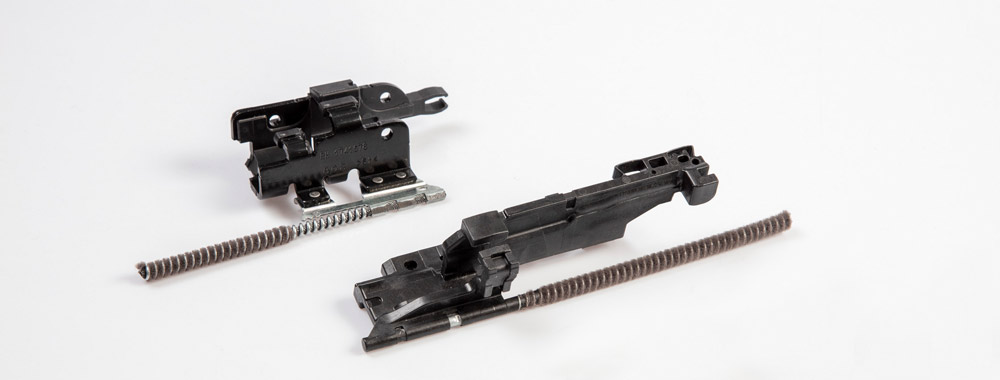

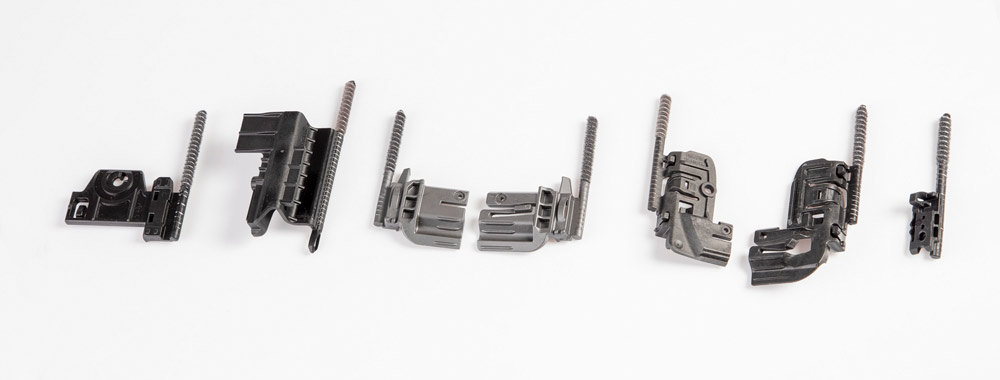

Sliding blocks as connectors

For adaptation purposes, helix cables can be supplied with moulded plastic fittings and/or metallic connectors or reinforcements.

A small moulded cap on the other end reduces potential noise.

Flock/flock yarn

Flock yarns differ in terms of the

Flock yarn is used for noise reduction purposes.